Note, the accuracy of TruckLoader reports is dependent on the accuracy of input. Thus, it is essential to provide accurate data to TruckLoader.

Obtaining the parameters from an empty truck

There are four different ways to get this information:

- You can find this information on the truck plate of your vehicle. Enter this information in TruckLoader.

- Take a photo of your vehicle and upload it to TruckLoader. This feature is unique to TruckLoader software! Using the photo image TruckLoader will identify your vehicle. In this case, your parameters are adde from our database.

3. Select from hundreds of models available in the TruckLoader database to match your vehicle. By selecting the correct model, corresponding parameters are automatically entered in TruckLoader.

4. Determine the weight of the vehicle by using scales. Equally, the dimensions are obtained by measuring the vehicle. See PepsiCo video for more details.

Determine the load parameters

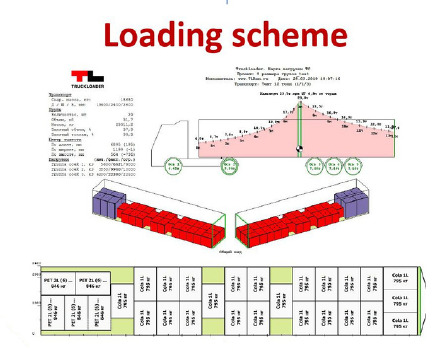

Loading scheme optimization

Truck loading in the warehouse

Obtaining the parameters from full truck

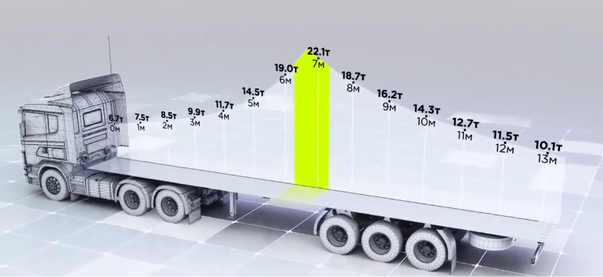

For demonstration, if you have an 18-tonne truck with a capacity of 9.5-tonne payload. Assume, you load a 9-tonne payload, you would expect the final weight to be (18+9=27) 27 tonnes.

Now compare the final weight with the output from TruckLoader. The two values should be equal. Of course, if there is a variation, then you may need to investigate further the reasons for this difference.

What if I don't have the scales?

Would you like to know more?

Would you like to know more about the loading and weighting process? Do you have any specific questions? Please feel free to contact us. We will be morethan happy to help.